This scarce development of the aneroid barometer or altimeter, patented by Colonel H.S.S. Watkin in 1898, was born of poorly performing pressure sensing capsules. It had been known for some time that a first reading before an ascent of some high place would not agree once the observer returned to the same elevation even if the barometric pressure had not varied. The phenomenon in metallurgical terms is known as hysteresis which has to do with the elasticity of metals. Simply, if a load is applied to a metal component causing the component to deform, once the load is removed the component should return precisely to its original dimension. However, dependent upon the metal, its elastic limit may have been exceeded, in which case the dimension may become temporarily altered, taking time to ‘creep’ back to its original dimension, or even permanently altered. As far as pressure sensing capsules of the time were concerned, it was this creep factor that caused the greatest problem, although temperature was also an issue as it meant that the elastic constant shifted. At this point, the science became very inexact from the user’s point of view and so an alternative had to be found.

Manufacturers at the time tried to address this problem by working on the materials from which capsules were made; inventors approached the matter from a different direction. The length of time the capsule material was exposed to its newly acquired dimension was found to have a significant affect on its ‘memory’ and thus its recovery time to standard dimension.

Colonel H.S.S. Watkin, formerly of the Royal Artillery, Chief Inspector of Position-Finding in the War Department, and inventor of a number of enhancements to aneroid instruments, determined that if the capsule could be ‘put out of gear’ for the duration of the ascent, only activated at the zenith, a reading taken, then the capsule ‘put out of gear’ again, it might follow that the ultimate reading taken at the start point might more closely agree with the first reading prior to ascent.

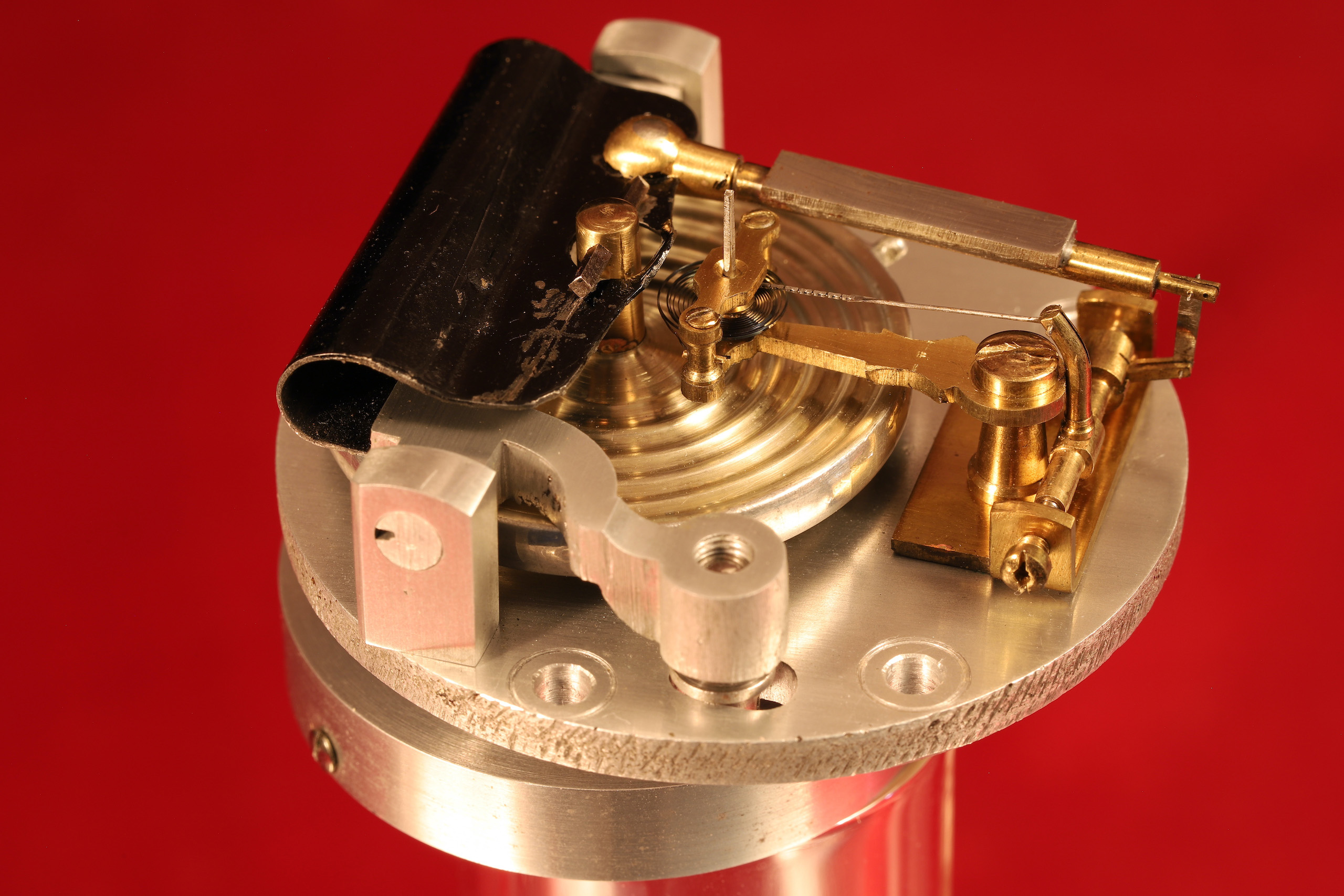

Watkin’s mechanism is quite simple: in normal aneroid barometers of the Vidie pattern, the lower side of the pressure sensing capsule is securely anchored to the chassis, achieved with a centrally mounted boss and threaded spigot which passes through a hole in the chassis and is securely held in place with a nut. Watkin’s patent mountain barometer allows that the capsule may, by way of a wheel, either draw the capsule to the top face of the chassis (its ‘active’ position) or allow the capsule to collapse to a dimension where it can no longer be affected by shifts in pressure. The capsule is ‘out of gear’.

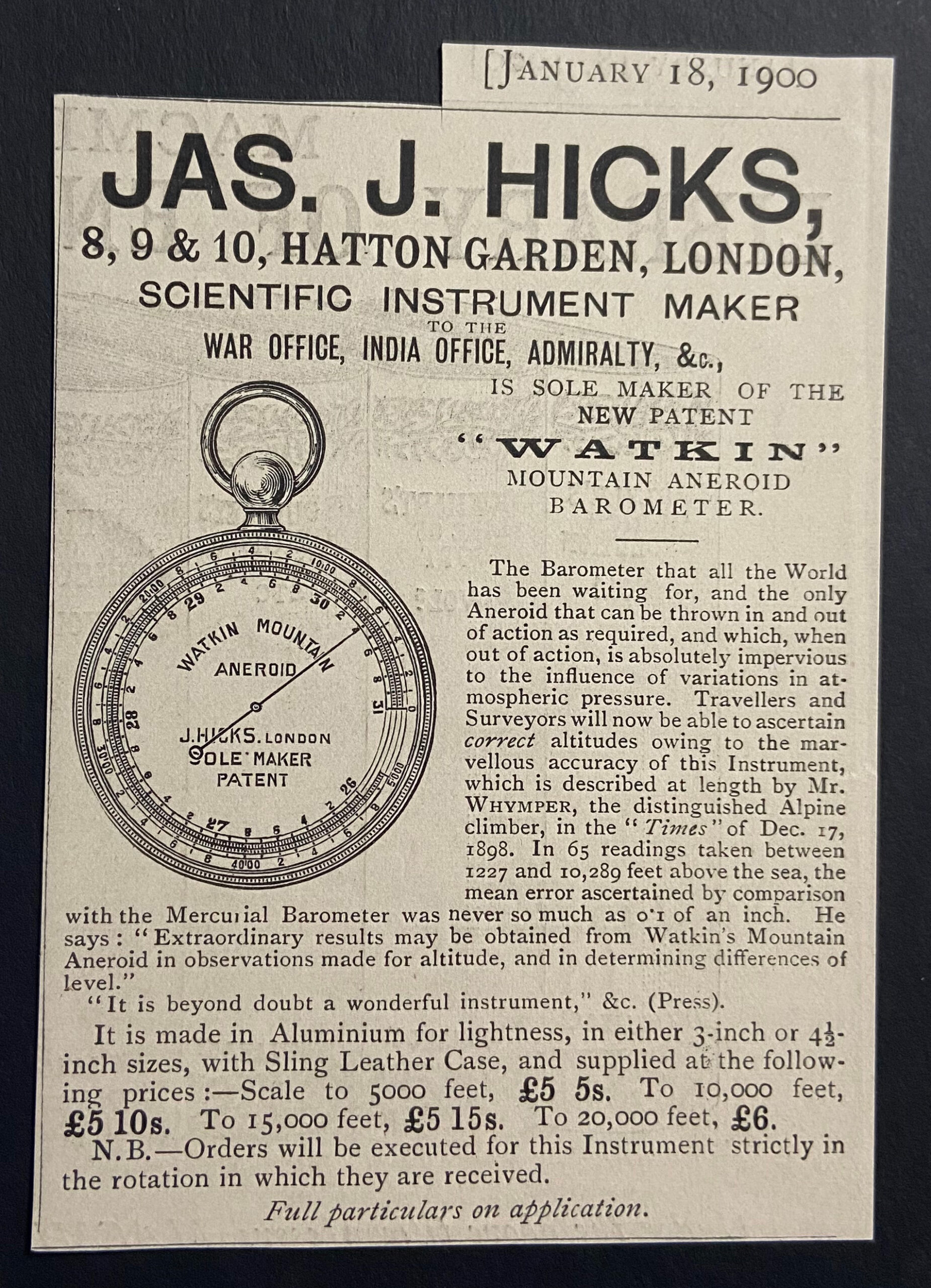

The esteemed mountaineer and explorer Edward Whymper thoroughly trialed a prototype of what would become the Hicks Mountain Barometer against a standard mercury mountain barometer in the Alps, observing that the differences between the reading on the mercury barometer and the Watkin mountain barometer were very slight – indeed, “upon two occasions Col. Watkin’s instrument read so truly against the mercurial that I was unable to detect any discrepancy between the two instruments.” Whymper reported his findings in a letter to The Times, 17th December 1898, stating “I feel confident that, in the hands of those who will give the requisite attention, extraordinary results may be obtained from Watkin’s Mountain Aneroid in observations made for altitude, and in determining differences of level.”

There is little other known contemporary commentary on this instrument and, to be fair, it is doubtful that the extra cost of the instrument was seen as good value to end users. Certainly it was much more expensive than a standard altimeter of the time.

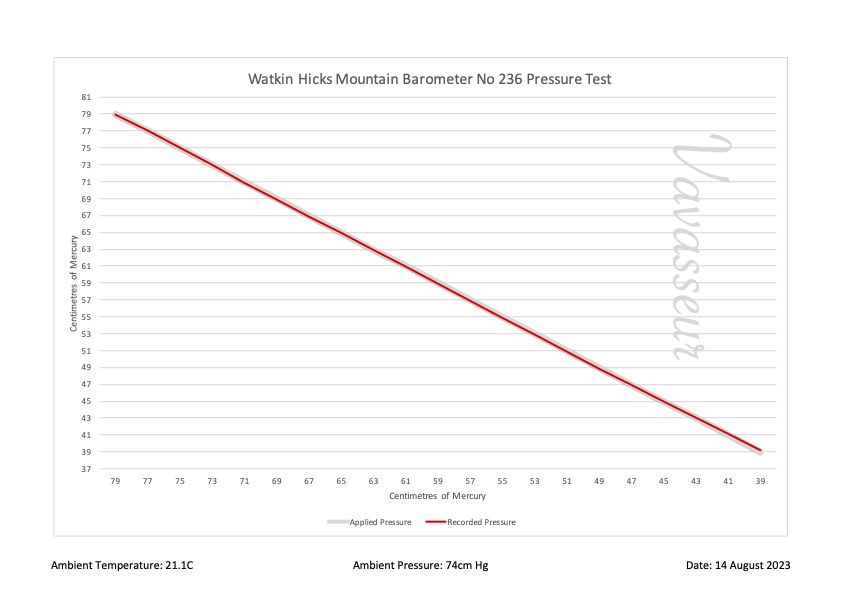

James Hicks generally produced some good instruments, though some, especially in the series of his Watkin Hicks multi-rotation open scale instruments, left a little to be desired. This series of instruments, of which I can accurately document four, serial numbers 33, 227, 228 and 236, are amongst as good in terms of making as about any of his competitors. This is a thoroughly well engineered instrument. It does not appear to have been a success, borne out by the fact that very few are seen. It may well be that the serial numbers are consecutive and dedicated to this particular instrument which, if correct, would suggest only a few hundred were made – my guess at this stage, based on the evidence, would be less than 300

Critical analysis of the instruments yields up at least one major disadvantage so far as function is concerned. The capsule is brought into action by turning the wheel mounted on the back of the instrument by folding out the fly piece generally held in its stowed position by a small detent. It is vital that the wheel is turned clockwise to its full extent before a reading is taken as if not fully wound up by even a fraction of a degree the reading shown on the dial will be false. Unfortunately in this design no mechanism is provided to ensure that this is so and that the wheel remains in position.

On the other hand, the thick brass clover-leaf washer or wheel, a counter, is a clever part of the mechanism that allows a precise number of rotations of the wheel in either direction, a pin extending from the hub of the wheel engaging in an adjacent slot on each rotation as it does so it causes the counter to move though a set number of degrees. This mechanism prevents over-tensioning or indeed the wheel unscrewing completely from its threaded spigot.

The engineering involved in the manufacture of this instrument is quite involved, the case apparently machined from a solid billet of aluminium – not a cheap exercise bearing in mind the cost of aluminium at the time. The standard of construction is generally high and, in point of fact, far better than some of the other Watkin Hicks instruments – indeed, it stands quite apart from anything else that I have seen that the duo produced, begging the question, why?

I suggest that this was not made by Hicks but probably by Casella for Hicks and here are some reasons why I believe this is possible: the standard of engineering is of that of Casella generally, one of the very best makers of the time; the difficulties in engineering and production of components would have been more easily accomplished by Casella than by Hicks; Casella often provided a screwed-down dust plate coving the calibration port, a feature I believe only to be found on their instruments, but this is also found here, though not seen on any other Watkin Hicks or Hicks instrument; and finally, of course, Hicks was well known for buying in instruments and labelling them his own.

In conclusion, I would say that this mountain barometer was a very important innovation but not, however, a commercial success as witnessed by the very few that survive. The advances of metallurgy in capsule making soon reduced the issue of hysteresis to very acceptable levels, but also this instrument was only really useful if one was making quicker transits across altitudes when in reality changes in altitude were generally slow and progressive, allowing greater time for capsules to return to proper dimension.