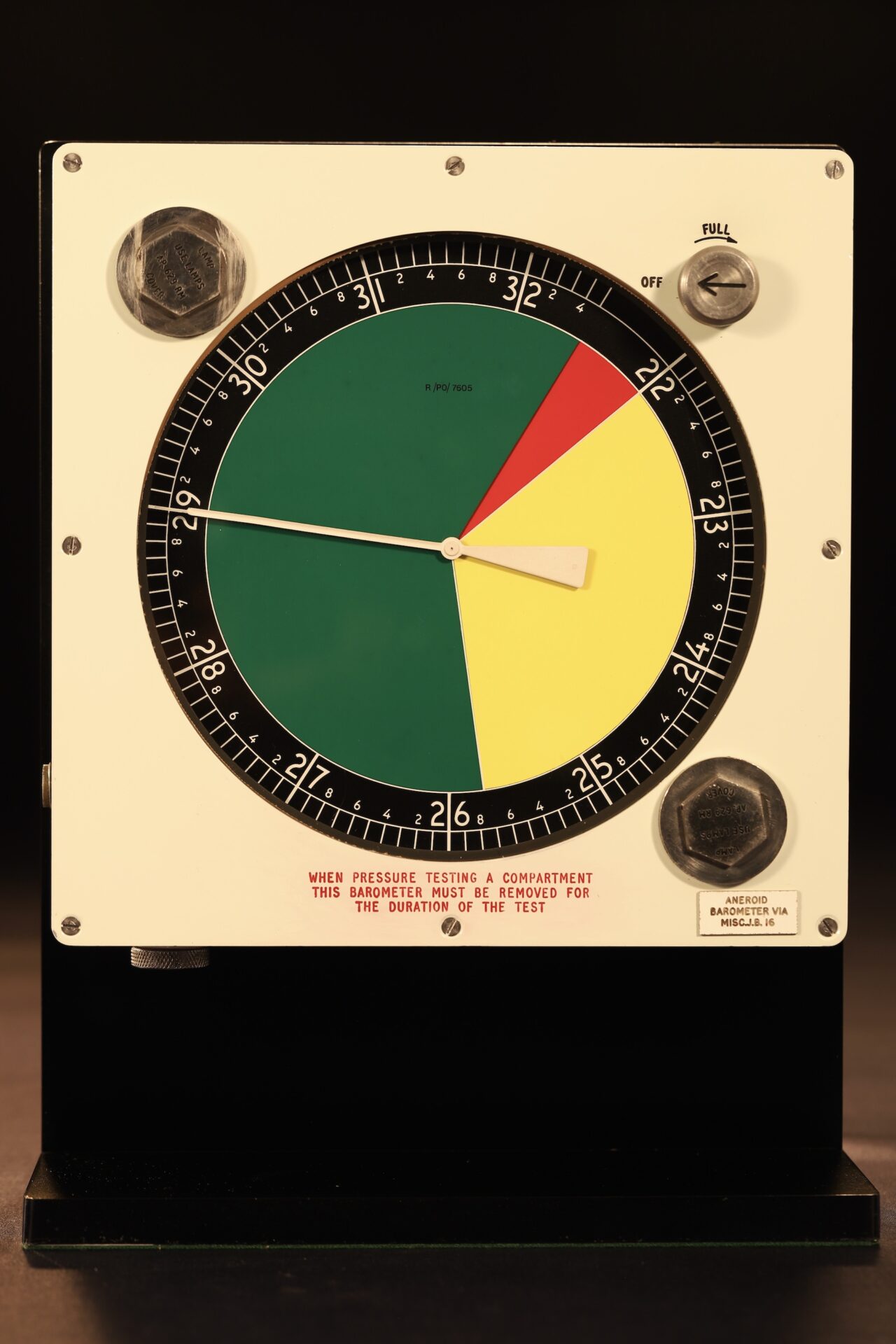

Submarine barometer having 8” sector coloured brass dial calibrated in inches of mercury with a range from 22 – 32.5” Hg, the scale set on a black ground and divided in white to 1/10ths”, the sectors delineated as: safe – colour green 25.8 – 32.5; pressure correction required – colour yellow 25.8 – 22; extreme risk hypoxia – colour red <22. The upper part marked “R /PO/ 7605,” white painted alloy pointer. Red lamp illumination diffused via a heavy bevelled plexiglass dial ring with lamp mat preventing egress of illumination directly outward. All set beneath a heavy plexiglass.

The front panel with twin screw down lamp covers labelled “Lamp Cover, Use Lamp AP.629 RM,” illumination rheostat/switch, labelled “On” and “Full” with direction arrow, the lower part annotated in red “When pressure testing a compartment this barometer must be removed for the duration of the test.” Applied stores plate marked “Aneroid Barometer V1A, MISC.J.B. 16.”

Twin 2” capsule driven finely pivoted rack and pinion movement with low pressure protection and temperature compensation, all constructed within a light alloy cage, upper geared circumference, short supported correction shaft with bevelled gear and extending to outer case with single screw type slot positioned at the case bottom. The 22 volt lighting circuit with substantial rheostat/switch, twin lamp holders and case side mounted connector. Threaded drain plug to lower case.

All contained within a cast aluminium flanged case, the side with manufacturer’s plate stating “Aneroid Barometer Admiralty Pattern No 750, Manufacturers Type No KBA 0501 Serial No GI. 315/61 Kelvin & Hughes Ltd, Basingstoke, Year of Manufacture 1961.” Adjacent orange stores label marked “M.O.D. (Navy Dept), Calibrated, Valid Until” and “HM Dockyard Rosyth.”

Condition: Restored as original. Movement serviced, and calibrated under laboratory conditions.

Comments: Regulating the pressure, temperature and, in particular, the partial pressures of the constituent gasses of breathing air in the boat is a primary consideration. In an often closed environment, extreme variations of these parameters, unless carefully monitored, may reach unacceptable limits likely to cause lowered performance of the crew at best and, in the extreme, death.

This instrument is designed to monitor one of these parameters, air pressure,. This may vary for a number of reasons, becoming dangerous to the crew very quickly unless continually monitored and corrective measures taken to re-establish safe limits. The principal cause of pressure fluctuation is due to the induction system connected to the diesel engines. These boats were equipped to run submerged at about periscope depth on diesel engines, the air down into the boat via a Snorkel or Snort. This equipment was rigged with a float system designed to prevent salt water from finding its way down the snort and into the engines, an ever present risk being that the induction system becomes restricted or blocked causing air to be drawn into the engines from inside the submerged boat. At this point the boat’s ambient breathing air pressure rapidly drops, and this coupled, with the likely higher than normal levels of CO and CO2, could mean the partial pressure (PP) of oxygen easily falls below safe limits leading very quickly to hypoxia within the crew.

Positive pressure, ie higher than standard pressure 29.95”Hg, could easily occur, the root cause of this being leaks on the HP air systems associated with ballast tanks and torpedo firing systems. Particularly very high pressure for extended periods could conceivably lead to the PP of nitrogen rising beyond safe limits inducing nitrogen narcosis – in certain circumstances, the crew might exhibit symptoms associated with the bends when normal or low pressure occurs. This is dependent upon the pressure applied and the duration of that exposure. There is a recorded incident in WW2 of a crew member actually being fired out of the hatch in the fin and going over the side. These are extremes but illustrate the potential hazards and therefore the great importance of this instrument in safeguarding the crew.

The “O” class boats carried two such barometers, one mounted in the Control Room on the port side and aft of the steering position, and another in the Engine Room on the deck head over the Starboard diesel. The Control Room barometer was the responsibility of the Officer of the Day, his job to continually monitor the indicated pressure especially when dived and running on diesels – should an issue arise, this would be immediately reported to the Engineer Officer in the Engine Room. Corrective action could then be taken to restore pressure to within normal limits.

A really very rare and most impressive item, the variable red illumination fully functional, the instrument working exceptionally well with high precision, stepless progression and highly sensitive. Mounted on a bespoke ¼” aluminium plate stand.

Dimensions:

Stock No: BA1849

Price: Vavasseur Archive - not currently for sale